You are here: Home >

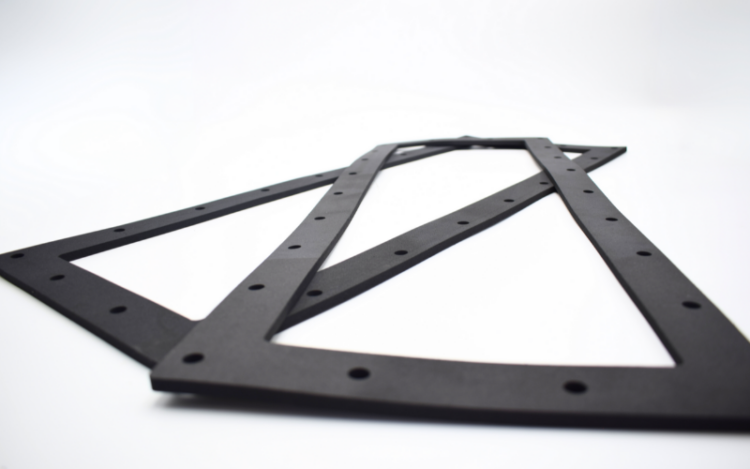

At R4 Gaskets, we manufacture pipe flange gaskets to any standard table size using advanced in-house CNC gasket cutting technology. Our gaskets are cut from a variety of sheet materials held in stock, ensuring quick turnaround times and high precision. Download our flange gasket datasheets to find the specific flange type you need, and refer to our guide for detailed instructions on how to measure a gasket accurately.

Understanding Pipe Flange Gaskets

Pipe flange gaskets are the most common type of gasket, typically circular and available with or without bolt holes, depending on your requirements. Two of the most crucial dimensions for a flange gasket are the inner diameter (ID) and outer diameter (OD), ensuring a correct fit for your application.

To measure these dimensions:

- Use a tape measure or ruler.

- Place the measuring tool edge to edge over the gasket face and note the measurements.

For gaskets with bolt holes, it’s important to measure the gap between opposite holes accurately. Depending on the gasket size, a digital calliper provides the most precise reading, but a tape measure or ruler can also be used.

To calculate the pitch circle diameter (PCD):

- Measure from the inside of one hole to the inside of the opposite hole.

- This method assumes equal hole diameters.

Fast Lead Times and Comprehensive Selection

We offer fast lead times on both standard and bespoke manufactured parts. Our extensive selection of gasket materials is available in rolls, sheets, or precisely cut components. Standard materials are ready for same-day dispatch, while non-standard parts can be swiftly fabricated using our CNC cutting machines. Our team of experts is available to help you choose the ideal product for your specific application.

Choose R4 Gaskets for precision pipe flange gaskets, exceptional quality, and efficient service. Contact us today to discuss your gasket needs and benefit from our advanced manufacturing capabilities.