You are here: Home >

Lathe cut gaskets provide a quick and cost-effective alternative to our moulded or die-cut manufacturing processes. Produced by inserting a rubber tube into a mandrel, which is then turned on a high-speed lathe machine, this method allows us to create precision-cut gaskets efficiently. Utilising almost 100% of the material results in greater yields at a reduced cost.

Superior Performance and Versatility

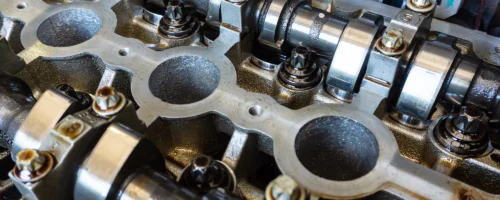

Lathe cutting is ideal for applications requiring a bevelled edge or tight tolerance. It is also suitable for producing gaskets with large outer diameters or small inner diameters. Lathe cut gaskets excel in static seal applications, maintaining their design and shape under continuous stress for consistent performance and long service life.

Wide Range of Sizes and Materials

We can produce lathe cut gaskets from tubing with outer diameters ranging from 6mm to 500mm and thicknesses starting from 0.5mm. Most rubber compounds can be cut using the lathe method, though very soft or very hard materials may not be suitable. If needed, we can manufacture custom mandrels to produce bespoke gaskets to your exact specifications.

Key Features

- Cost-efficient alternative to moulded and die-cut gaskets

- Quick turnaround time

- Ideal for small to large scale production runs

- Tight tolerances of .003 inches

- Suitable for large O/D and small I/D gaskets

- Greater control over gasket thickness

- Minimal material waste produced

- Best suited for simpler gasket designs

Potential Applications

- Static and radial seals

- HVAC gaskets

- Water well gaskets

- Vacuum sweeper belts

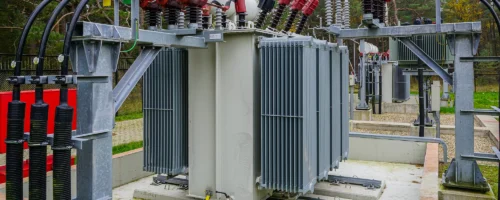

- Non-conductive insulation gaskets

- Food grade gaskets

- Filter gaskets

- Electric transformer gaskets

Choose R4 Gaskets for efficient, precise lathe cut gaskets that deliver reliability and cost savings. Contact us today to discuss your gasket needs and take advantage of our advanced manufacturing capabilities.