You are here: Home >

Our water jet cutting process utilises high-pressure water forced through a small nozzle, producing extremely clean and precise cuts on various material thicknesses. This method is ideal for creating complex gasket designs and shapes, especially with soft or delicate materials, as it places minimal stress on the material. This ensures the gasket retains its structural integrity while delivering clean cuts consistently.

Advantages of Water Jet Cut Gaskets

Water jet cutting offers several benefits, including faster production times compared to other methods. This allows us to manufacture prototype gaskets or small production runs with a quick turnaround. The precision of the water jet also maximises material usage, reducing waste and saving costs while shortening lead times.

The variable pressures achievable with our water jet cutting machine enable us to tailor each cut to the required material. This ensures consistent finishes and tolerances across all our water jet cut gaskets. High-pressure water can easily cut through very thick and laminated materials, making this method particularly useful for glass-reinforced gaskets that might crack during other manufacturing processes.

Expertise and Custom Solutions

At R4 Gaskets, we collaborate directly with you to ensure you get the best gaskets possible. With over 100 years of experience, we can recommend the optimal materials and methods for any application. Contact us today for all your gasket needs.

Key Features

- Reduces material stress, preserving structural integrity

- Suitable for both soft and hard materials

- Capable of cutting thick and laminated materials

- Clean cuts to high tolerances

- Quick turnaround times

- Ideal for small to medium production runs

- Minimises material waste for improved yield

Potential Applications

- Complex and tight tolerance gaskets

- HVAC gaskets

- Missile and torpedo gaskets

- High-temperature and high-pressure gaskets

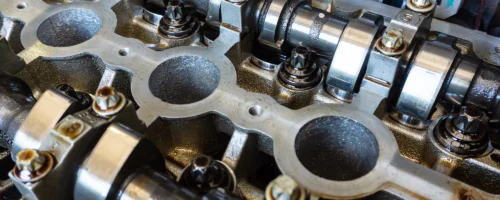

- Manifold gaskets

- Turbine gaskets

- Hydraulic gaskets

- Industrial gaskets

Choose R4 Gaskets for precision water jet cut gaskets that deliver exceptional quality and efficiency. Contact us now to discuss your gasket requirements and benefit from our advanced cutting technology.