You are here: Home >

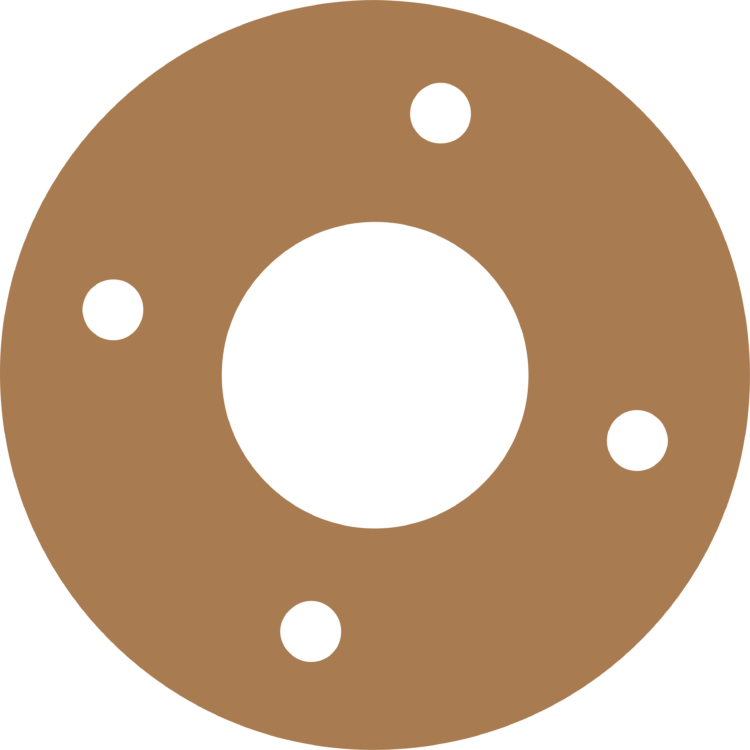

At R4 Gaskets, our low compression cork gaskets are made from a medium-density material using a nitrile rubber binder. This ensures the gaskets are ideal for noise and vibration control applications, offering excellent oil and fuel resistance for superior performance in specialised environments. Our low compression, rubber-bonded cork is highly flexible and durable, featuring impressive recovery and tensile strength properties.

Key Features

- High Quality Material: Ensures long-lasting performance and durability.

- Low Compression Rates: Maintains effective sealing under pressure.

- Noise & Vibration Control: Ideal for reducing noise and vibrations in various applications.

- Oil & Fuel Resistance: Provides superior resistance in environments exposed to oils and fuels.

- Flexibility: Highly flexible and easy to work with.

- Customisable: Available in thicknesses from 1.5mm to 25mm, and can be cut into strips or bespoke gaskets to meet your exact specifications.

Custom Manufacturing

Using advanced CNC machinery, R4 Gaskets can produce low compression cork gaskets tailored to your requirements. Whether you need standard strips or custom gaskets, we ensure precision and quality in every product.

Applications

- Noise & Vibration Control: Effective for machinery such as pumps, presses, looms, and motors.

- Rail & Subway Isolation Pads: Ideal for use in runways, rail, and subway isolation pads.

- Acoustic Insulation: Suitable for walls, ceilings, and piping in building and construction applications.

- Civil Engineering: Used in acoustic suspension elements and systems.

- Automotive: Provides vibration isolation and noise reduction in vehicles.

- Manufacturing Plants & Production Lines: Enhances machinery performance by reducing noise and vibrations.

Contact Us

Choose R4 Gaskets for high-quality, low compression cork gaskets that meet your specific needs. Contact us today to discuss your requirements and find the perfect gasket solution for your application. For guidance on accurately measuring your gasket, please refer to our detailed ‘How to Measure a Gasket‘ guide.