by Dominique Jurd

When it comes to reliable sealing solutions, nitrile rubber gaskets stand out as an industry favourite. Known for their exceptional resistance to oil, fuel, and temperature extremes, nitrile gaskets are ideal for a wide range of applications, from industrial machinery to food processing. In this guide, we’ll explore the key features, benefits, and material grades of nitrile rubber gaskets, showcasing why they’re a preferred choice for demanding environments.

The Resilience of Nitrile Rubber

Nitrile rubber is renowned for its superior resistance to swelling when exposed to oil and fuel substances. This resilience ensures that nitrile gaskets maintain their sealing properties in even the harshest environments, making them indispensable for applications like engines, hydraulic systems, and high-temperature machinery.

Temperature Resistance

Nitrile gaskets offer an impressive operating temperature range, making them highly effective in extreme heat. This versatility makes them a go-to material for applications where maintaining a seal in challenging temperature conditions is essential.

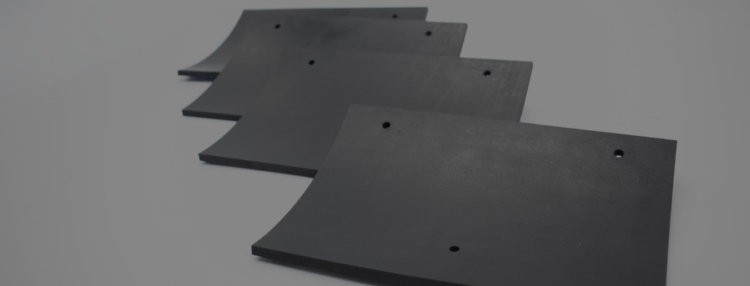

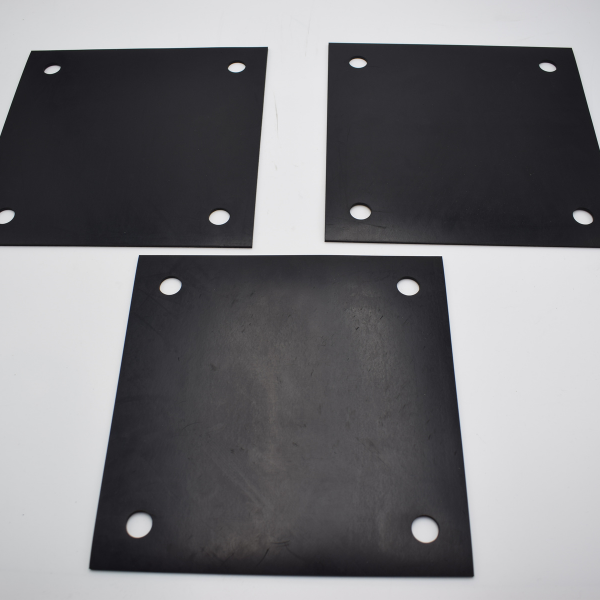

Precision Manufacturing

At R4 Gaskets, we manufacture nitrile rubber gaskets using high-quality nitrile sheets, ensuring seamless production without joins or defects. With advanced precision cutting technology, we create gaskets of all shapes and sizes, from simple designs to complex custom profiles, with unmatched accuracy.

Nitrile Rubber Grades and Applications

To meet diverse industry requirements, we supply nitrile rubber gaskets in a range of grades and compounds, each tailored for specific applications:

- BS2751 Grade Nitrile

- Conforms to British safety standards.

- Exceptional oil, fuel, and chemical resistance.

- Ideal for industrial and construction applications.

- Fuel-Resistant Nitrile/PVC Blend

- Designed for fuel processing and transportation.

- Minimises material swelling and ensures fuel purity.

- Food Contact Grade Nitrile

- Meets FDA 21 CFR 177.2600 standards for food and beverage contact.

- Combines flame retardance and high-temperature resistance, making it suitable for food production environments.

- Economy/Commercial Grade Nitrile

- Cost-effective option for low-pressure applications.

- Suitable where extensive oil and fuel resistance is not critical.

- Hydrogenated Nitrile (HNBR)

- Enhanced resistance and durability compared to standard nitrile.

- Performs well in abrasive and hard-wearing environments.

- Gas-Approved Nitrile

- Certified to BS EN 682:2002 for gas and hydrocarbon fluid applications.

- Excellent tensile strength, flexibility, and resistance to deterioration.

Explore Our Comprehensive Range

At R4 Gaskets, we simplify the selection process with a wide variety of nitrile rubber grades tailored to meet your unique requirements. Our online nitrile rubber section offers detailed information, including material descriptions, typical applications, standard thicknesses, and datasheets.

Expert Guidance Every Step of the Way

Not sure which nitrile gasket is right for your needs? Our knowledgeable team is here to help. Contact R4 Gaskets today for expert advice, technical support, and tailored solutions. Trust us to deliver the perfect nitrile gasket for your application.